Ryukyu Indigo Dye

Alvana, Corgi, NEAT, PADMORE & BARNES collaborated with 4 brands to release bespoke items.

ALVANA "RYUKYU INDIGO DYED TEE"

ALVANA "RYUKYU INDIGO DYED TEE"

CORGI "RYUKYU INDIGO DYED SOCKS"

CORGI "RYUKYU INDIGO DYED SOCKS"

NEAT for SOUTH STORE “RYUKYU INDIGO DYED NEAT CHINO”

NEAT for SOUTH STORE “RYUKYU INDIGO DYED NEAT CHINO”

PADMORE & BARNES for SOUTH STORE “RYUKYU INDIGO DYED P404”

PADMORE & BARNES for SOUTH STORE “RYUKYU INDIGO DYED P404”

All of the bespoke items have one thing in common, which is that they are dyed with Okinawa's traditional dyeing "Ryukyu indigo". There are pure indigo (chemical dye) and natural indigo (real indigo, natural indigo) in indigo, but Ryukyu indigo is natural indigo.

I would be happy if it would be an opportunity for you to know Okinawa's Ryukyu indigo dyeing even a little. I planned with that in mind.

From here, we will introduce the process of “Ryukyu indigo dyeing”. "Ryukyu Ai Research Institute", which carries out everything from cultivation of Ryukyu indigo, which is the raw material, to dyeing in-house, cooperated with the interview and contracted the bespoke Ryukyu indigo dyeing.

I spent half a year making and interviewing the work, so please take a look.

Start by growing seedlings. Transfer the grown seedlings to the field. Although Ryukyu Aiba is an Okinawan variety, it is vulnerable to direct sunlight and is very delicate. Exaggeratedly speaking in the vinyl tent, we will carefully manage and grow overprotection. Aiba was raised with love. Harvest time is twice a year. (June-July, October-November)

Start by growing seedlings. Transfer the grown seedlings to the field. Although Ryukyu Aiba is an Okinawan variety, it is vulnerable to direct sunlight and is very delicate. Exaggeratedly speaking in the vinyl tent, we will carefully manage and grow overprotection. Aiba was raised with love. Harvest time is twice a year. (June-July, October-November)

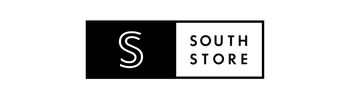

Hundreds of kilograms of indigo leaves can only be used as dyes. Soak the harvested indigo leaves in water and wait for the pigment components to seep out from the leaves and stems. Pigment components are gradually extracted over time. Adjust the soaking time according to the temperature and water temperature. After extracting enough pigment from the indigo leaves, pull them up and remove the leaves. Immediately after removing the indigo leaves, there is a very beautiful emerald green liquid.

Hundreds of kilograms of indigo leaves can only be used as dyes. Soak the harvested indigo leaves in water and wait for the pigment components to seep out from the leaves and stems. Pigment components are gradually extracted over time. Adjust the soaking time according to the temperature and water temperature. After extracting enough pigment from the indigo leaves, pull them up and remove the leaves. Immediately after removing the indigo leaves, there is a very beautiful emerald green liquid.

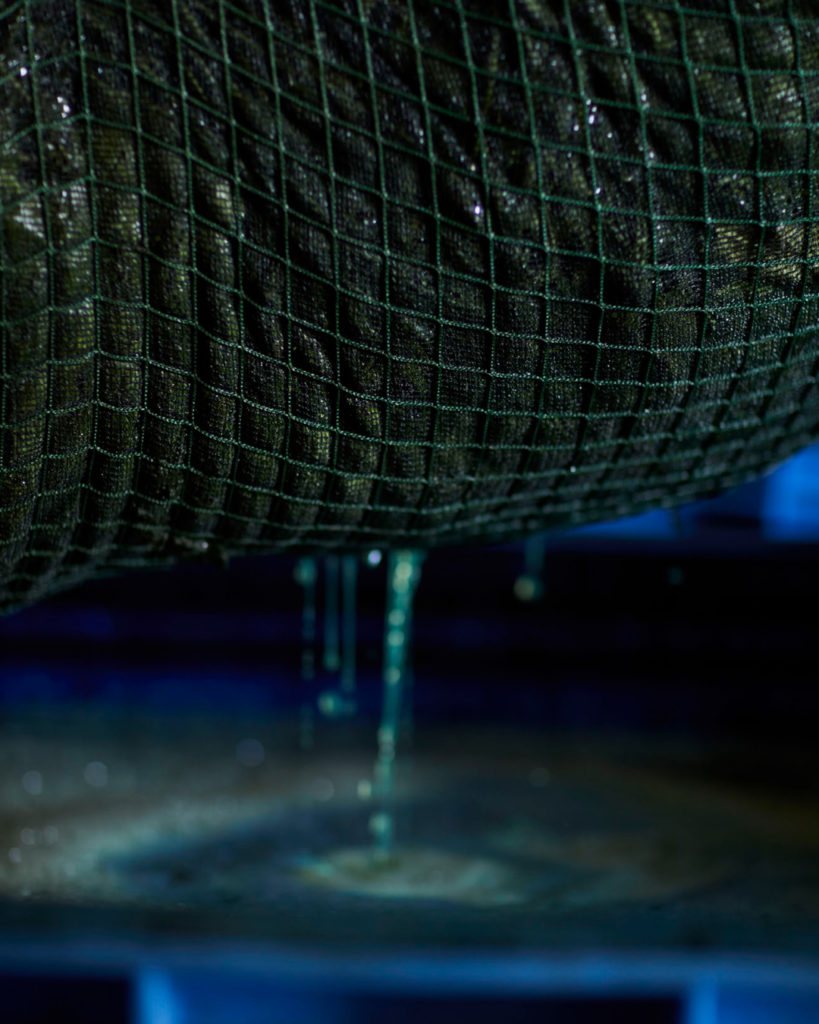

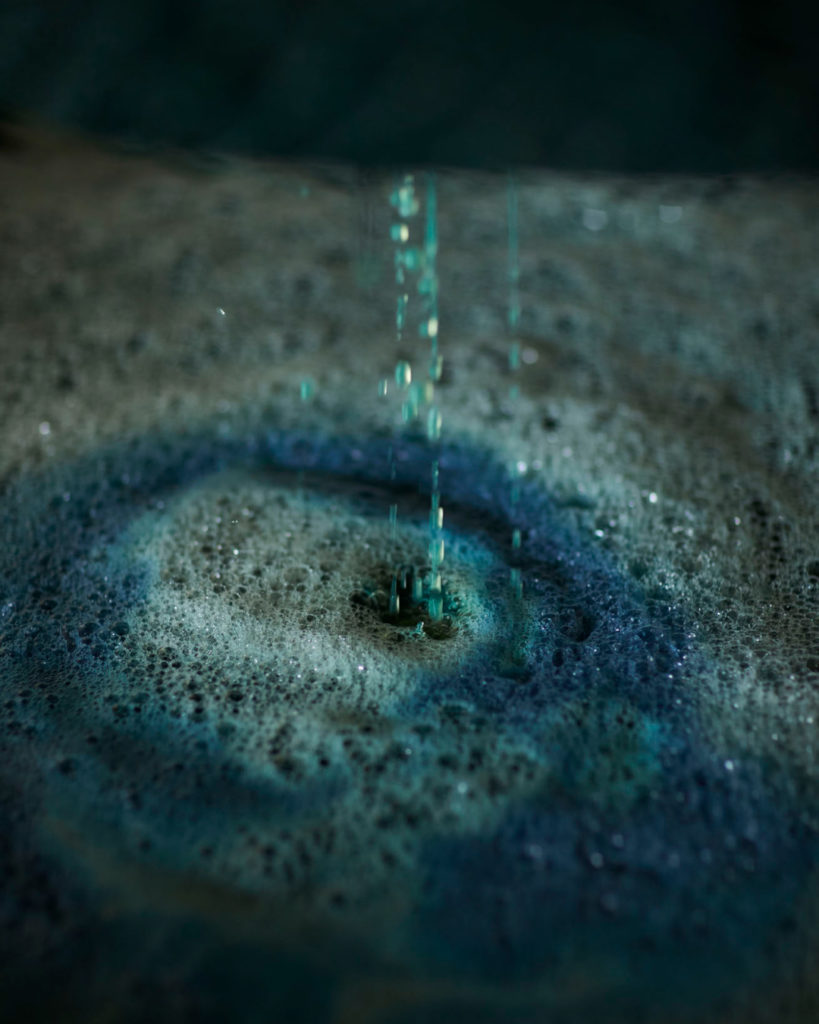

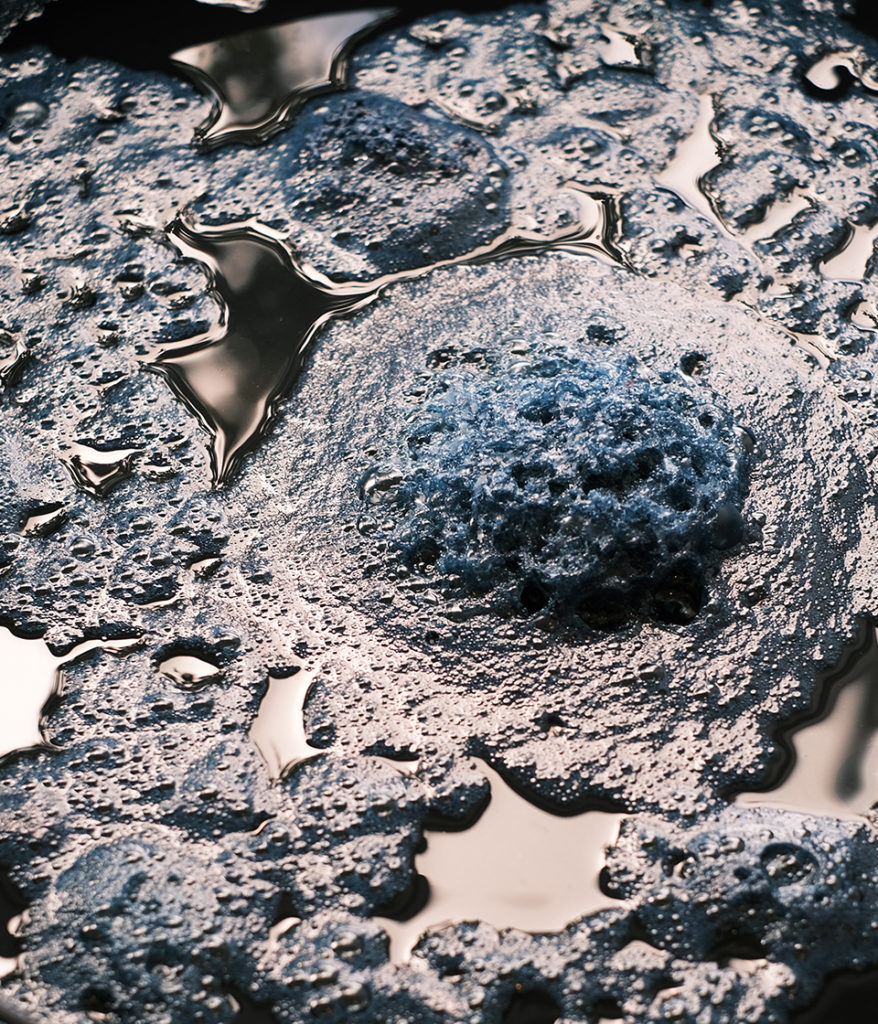

Once you have extracted enough pigment from the indigo leaves, dissolve the slaked lime in water and add it. After putting it in, stir it all the time to send air. The extracted pigment component and air are combined, gradually changing to a blue liquid, and blue bubbles are born. After the foam subsides, wait for the dye to settle and collect. It is Ryukyu indigo that has become a mass of pigment, and "precipitated indigo", an indigo pigment extracted from plant leaves.

Once you have extracted enough pigment from the indigo leaves, dissolve the slaked lime in water and add it. After putting it in, stir it all the time to send air. The extracted pigment component and air are combined, gradually changing to a blue liquid, and blue bubbles are born. After the foam subsides, wait for the dye to settle and collect. It is Ryukyu indigo that has become a mass of pigment, and "precipitated indigo", an indigo pigment extracted from plant leaves.

The indigo dye extracted from the leaves of the plant, "precipitated indigo," is actually not dyeable in this state because it is difficult for the pigment particles to enter the thread or cloth. In order to dye it properly, it is necessary to perform "indigo building" with the help of microorganisms.

The indigo dye extracted from the leaves of the plant, "precipitated indigo," is actually not dyeable in this state because it is difficult for the pigment particles to enter the thread or cloth. In order to dye it properly, it is necessary to perform "indigo building" with the help of microorganisms.

The mud indigo (precipitated indigo) is soaked in water and dissolved while removing impurities. Leave the indigo to settle and remove excess lye. Check the condition of the supernatant and measure the pH value. pH is an abbreviation for hydrogen ion concentration, and indigo dissolves in alkali, so you must always keep a constant pH. Also, since there are surprisingly few bacteria that can grow in an alkaline solution, maintaining the alkalinity can suppress the growth of bacteria other than the fermenting bacteria of indigo. When the pH drops, other bacteria can grow more easily. As other bacteria grow, the pH drops rapidly. In Okinawa, starch syrup and awamori are added to adjust the condition, while listening to Ai's mood every time.

Stirring twice a day, in the morning and in the evening, is essential so that the precipitated indigo does not rot. At that time, we will also check the pH value and adjust the value with slaked lime.

Stirring twice a day, in the morning and in the evening, is essential so that the precipitated indigo does not rot. At that time, we will also check the pH value and adjust the value with slaked lime.

The bubbly foam that collects in the upper layer of the dye is called “Ai no Hana” and is one of the indicators that the dye is fermenting well. Use it as a guideline to judge whether the indigo construction is progressing.

Once the indigo building has progressed, we will finally start dyeing the work. If the air is not properly removed from the indigo, it tends to become distorted and uneven, so each work is carefully dyed by hand. Dyed and exposed to the air to check the color. In order to bring out an even more beautiful indigo color, it is dyed over and over again. If you check the density and finish of the dye every time, even if you put it in the same dye at the same time, the way it is dyed, the color, and the density will be completely different depending on the humidity, temperature, and weather. Unlike chemical dyes, which can produce multiple copies of the same product, there are areas that are difficult to achieve even if you aim for them. Aizome is truly a once-in-a-lifetime chance.

Once the indigo building has progressed, we will finally start dyeing the work. If the air is not properly removed from the indigo, it tends to become distorted and uneven, so each work is carefully dyed by hand. Dyed and exposed to the air to check the color. In order to bring out an even more beautiful indigo color, it is dyed over and over again. If you check the density and finish of the dye every time, even if you put it in the same dye at the same time, the way it is dyed, the color, and the density will be completely different depending on the humidity, temperature, and weather. Unlike chemical dyes, which can produce multiple copies of the same product, there are areas that are difficult to achieve even if you aim for them. Aizome is truly a once-in-a-lifetime chance.

It is a dyeing method that takes a lot of time and effort, but it is the completion of the one and only “RYUKYU BLUE” that can only be produced by Ryukyu indigo dyeing.

What did you think. It takes a lot of time and effort to make Ryukyu indigo dyeable. And I think that the efforts of the "Ryukyu Ai Research Institute" to pass on this historical Ryukyu indigo culture to future generations are truly wonderful.

At SOUTH STORE, we will continue to collaborate with various brands to release Ryukyu Aizome items so that we can convey the charm of Ryukyu Aizome to many people.